This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

(812) 867-3496

Abrasion Wear Testers

Abrasion wear testers are needed for inks and coatings as well as general cosmetic surfaces of other types. The abrasive test is an accurately repeatable way to determine abrasion characteristics of these surfaces. Because of the small spot tested by the RCA Abraser Tester, surfaces that are non-flat, or with small lettering or graphics can tested easily and accurately. The Wet Abrader offers a method to abrade a wetted surface.

View Our Products Overview Video

View Our Fake / Knock-Off RCA Tester vs Original RCA Tester Video

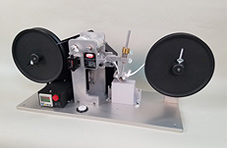

RCA Abrasion Wear Tester 7-IBB-CC

The RCA Abrasion Wear Tester is used to test surfaces for resistance to abrasion and wear. Typically used on painted or plated organic finishes, foil, and inked key pad lettering. This tester is widely used as a standard for many silicone key pad and membrane switch manufacturers. This abrader is used as a standard to the auto, appliance, cell phone, plastics, and coating industries. It uses an inexpensive roll of throw away abrasion paper. All build-up error is eliminated and consistent readings are easily obtained.

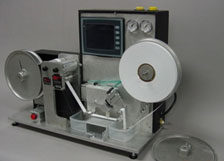

Wet Abrader WA-1010

Built on a combination of the RCA Abrader design, and the Finger Pressing design of the Pneumatic Finger Tester, this Wet Abrader adds the ability to apply a liquid to a special NTI Abrasive Media. This abrasive media is then pressed and rubbed against the specimen using a silicone finger probe. The test probe conforms to ASTM 1578 and ASTM 1597 Fig. 1.

Custom Test Equipment

While Norman Tool, Inc. is a leader in the abrasion wear test equipment industry, we also have a high quality CNC machine shop complete with an engineering design and development department. Equipped with the latest technology in CAD/CAM software, CNC milling machines, and lathes, we can provide design and build services to custom build the version of abrader test machines and button testing equipment for your particular testing applications. Whether it is button cycling, abrading, scuffing, or marring, or many other coating wear testing applications, our line of test equipment can be customized to suit your needs or we can design from the ground up.