This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

(812) 867-3496

Norman Tool Advantages

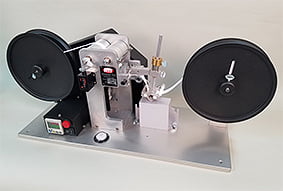

Norman Tool has been in the test equipment business since 1964. During this time we have obtained knowledge in coatings abrasion as well as general button testing, keypad testing, and membrane switch testing.

View Our Company Video

View Our Fake / Knock-Off RCA Tester vs Original RCA Tester Video

Small Abrasion Area – Great for small lettering and printing. Samples can be relatively small or the size of a standard test plaque.

Variation Distribution – Cycle counts across a single sample can be averaged and variations calculated. So, not only the averages, but the standard deviations can be compared from one sample to another and becomes a great comparison tool for different coatings that are very similar to each other.

Analyze Curing Process – The RCA tester has been used to determine changes in a coatings abrasion resistance during the curing period.

Can Test Concave and Convex Surfaces – Great for keypads, buttons, contoured surfaces such as on a computer mouse, writing pens and other non-flat items.

Automatic Residue Removal – Residue from the abrasion material and abraded surface is naturally wiped clear of the abraded area being tested. No vacuum of debris is needed. Continually uses clean un-abraded media. Media is disposable and can be discarded at your local paper recycle center if desired.

Stability in Abrasive Media – Abrasive quality of the abrasion media does not change during a test. Unlike a Tabor Tester, the Norman Tool Abrader does not use a grit type wheel. The Tabor Abrader wheel surface may collect and continue to accumulate unwanted debris during contact with the tested specimen, then abrade the specimen with the unwanted debris during the following revolutions during the remainder of the testing with the wheel.

Variable Load Settings – 3 different load settings can be set based on your desired selection.

Norman Tool wants to provide results and not just provide equipment. We want to make sure you have the ability to get test data that means something to your company to maintain or improve your products quality. So, we offer test services, test equipment rentals, and rent to own. We may be able to help guide you in setting up test criteria for a new test program as well as work with you and your parts vendors at the same time to ensure you can be set up for comparable data. Contact us to see what we help you with.

Warranty

All Norman Tool Products have a 6 month warranty from date of purchase. Contact Norman Tool, Inc. prior to returning products with Serial Number or Lot Number of product prior to returning.

Other Capabilities

Norman Tool is dedicated to providing equipment to provide testing products for abrasion wear, button testing, and Finger contact testing. If your application requires something a little different, please contact us to see if we can develop a customized version of our abrasion testers or custom button pressing tester for your unique application.

We have a full machine shop and prototype shop. With our experience with test method creation, test development, and cosmetic wear on products, we can help you with your wear testing program.

Finger Pressing Test Probes are supplied by Norman Tool as well. Ask us about our abilities to supply a variety of silicone finger probes or other custom test probes, metal scratch and scuff test probes or other special needs that you may have.