This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

(812) 867-3496

UST® – Universal Surface Tester

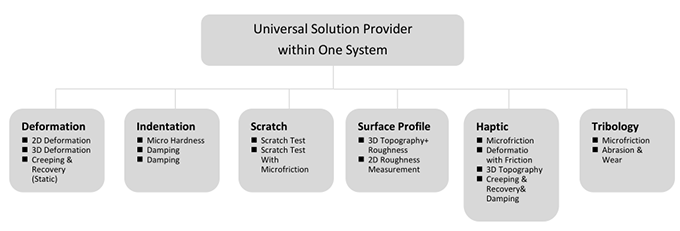

Adequate measurements are of great importance for a reliable simulation and evaluation of micromechanical properties of materials and surface coatings, such as deformation or haptics. As material and coating behaviour can vary considerably, a series of proper, real-time, quantitative measurements have to be performed with high resolution in the right dimension.

UST®-Universal Surface Tester, is by far the only open multi-modular system that provides a complete mechanical testing solution for the evaluation of bulk materials and surface coatings. Its unique configuration allows for a wide range of tip choices with various materials and sizes ranging from nanometer to centimeter.

Among various kinds of commercial available in-line material property testing instruments, UST® is by far the only tester which close the gap between the traditional macro-mechanical testing machines and nanoscale machines, e.g. nano-indentator and AFMs.

UST®

- One machine for all tests

- Same resolution (60nm)

- No need for correlation

- Local resolution

- Continuous measurement

- Surface structure combined with properties

Other Systems

- One machine for one type measurement

- Different resolution

- Need for further correlation

- No record with local resolution

- Point by point measurement

- No surface structure vs. properties

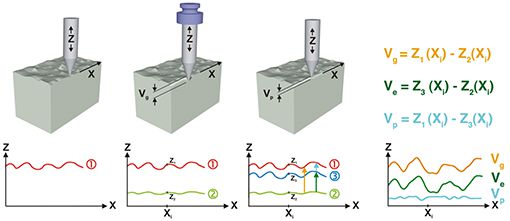

Measurement Principles

The UST® measurement procedure consists of a mechanically scanning by a stylus on the sample surface along a straight line several times. During this patented MISTAN procedure, the stylus is moved on the surface either without load or with a defined load.

- Scan with no load. Surface structure is continuously determined.

- Scan on the same path with additional load to determine total deformation.

- Scan on the same path with no load to determine the elastistic deformation.

- Total deformation = Step 1-Step 2;

- Elastic deformation = Step 3-Step 2;

- Permanent deformation = Step 1-Step 3

Basic Unit

UST®-100 with load range of 1 mN-100 mN

UST®-1000 with load range of 10 mN-1,000 mN for harder surfaces and coatings

Modules

A selection of 10 different modules is available for all types of measurements and applications. Each module includes all necessary hardware, software, suggested tip and necessary tools.

- 3D Deformation

- 3D Topography

- Scratch

- Microfriction (Standard)

- Abrasion and Wear

- Damping

- Viscoelasticity (Creeping & Recovery)

- Universal Hardness

- 2D Roughness

- TAX

Hardware Options

- Exchangable Measurement Head: UST 100 mN and UST 1000 mN

- Microscope: for documentation of the measurement process and results (photo function)

- Videocamera: for documentation of the measurement process and results (video function)

- Optical 3D Topography Module: non-tactile optical measurement of 3D topography

- Vacuum Plate Package: for fixing samples. Vacuum pump is included.

- Mini-Clamping Tool Set: fixing tool for harder samples

- Quick Plates: for easy and quick fixture of samples

Tip Options

Various sizes, geometries, customized tip available upon request